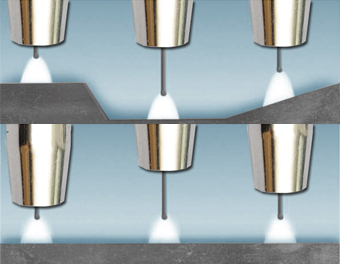

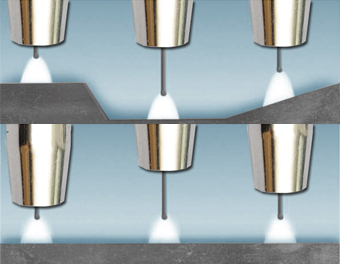

ST-ARC™ is the intelligent control of the Short Arc process, capable of handling automatically allvariations within the welding process.

The result is a short concentrated and stable arc 100% easier to control. The dynamic cold welding characteristics significantly lower the heat input reducing distortion, spatters, re-working and cleaning plus less weld time.ST-ARC™ is a standard feature of all Stel MIG / MAG Stel welders.

SELF COMPENSATION

Automatically compensates for any variation in

welding conditions caused either by irregularities of

the workpiece or the movements of the operator’s

hand. Ideal for awkward angles.

START CONTROL

The approach speed of the wire to the piece and welding dynamics are synergic and provide limit spatters at the start with every material. The dynamic synergic technology provides for an extremely smooth, spatter free Arc Ignition with all materials.

The approach speed of the wire to the piece and welding dynamics are synergic and provide limit spatters at the start with every material. The dynamic synergic technology provides for an extremely smooth, spatter free Arc Ignition with all materials.

VERTICAL POSITION

In a vertical UP position allows welding of thin material with separation up to 5mm gap.

THIN MATERIALS

Provides a smooth, controlled arc too at the lowest parameters with few spatters, good weldability of the edges, heating and reduced deformations for thin materials.

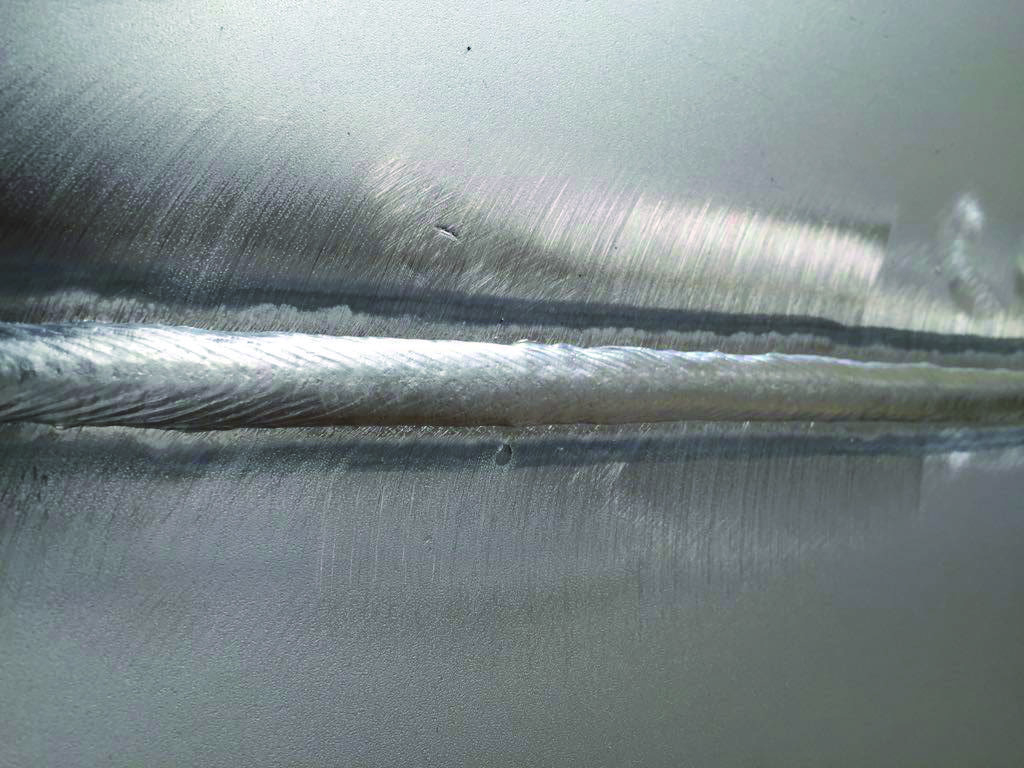

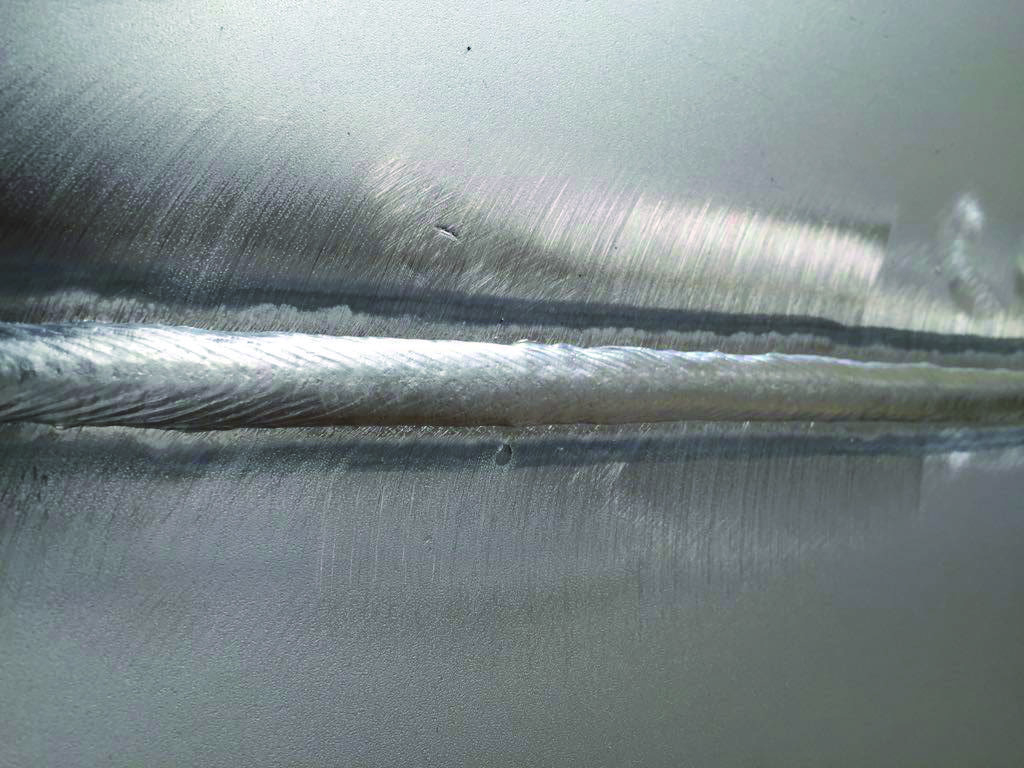

PAW™ is Precision Aluminium Welding. A new intelligent arc welding control on very thin Aluminiumthicknesses from 1 to 2mm.

The result is a very short and concentrated welding arc using 1.0mm wire with a standard MIG Torch.Therefore, there is no need for expensive push-pull torches, plus the additional cost saving of

using smaller wire diameters that cause problematic feeding.

PROGRAMS

There are 12 programs dedicated to aluminum.

Programs are synergic and pulsed. Two PAW™ programs (AlMg5 and AlSi5) are available for thin material thicknesses from 1 to 2mm.

PULSE

Preset synergic pulse programs greatly assists the operator with welding materials such as aluminum.

ALUMINUM

Owing to PAW™ technology, the IRON-MIG 221P power source can weld AlMg5 and AlSi5 aluminum wires avoiding the use of expensive push-pull torches and smaller diameter wires.

Normally pulsing is a “HOT” process. This has always caused problems of metal distortion (in particular thin material) and working speed.

Achieving a fast process has been the manufacturer’s challenge of the last years.

New processes have developed with many different names under the title SPEED.

What about the HEAT?

This is the real challenge that STEL has taken with the innovative i-Cold Pulse™. Reducing the thermal heat STEL have been able to increase the welding speed by 35%.

The arc is more concentrated and intense granting a better penetration.

i-Cold Pulse™: reduce heat input by improving performance

Find out how the Stel pulsed system reduces heat input by increasing speed by 35%.

Many have tried, Stel has succeeded.

Normally you know the pulsed welding in TIG and MIG, But not the pulse in electrode.STEL has been the first to develope this procedure with the range Max dp 171.-201C presented at ESSEN in the 2005.

Today this process has been studied and appreciated in all the European Universities of Welding.

The benefits

SELF COMPENSATION

> Better arc stability (expecially at low currents)

> Possibility to use the electrode with bigger diameter with thin materila thickness.

> Reduction of breakthroughs during welding with thin material thickness

> Better transfer control of the welding arc

> Easier control for the welder

> Improvement of the aesthetics of welding very similar to the Tig expecially with 4-5Hz frequency.

START CONTROL

> Ensures better and safer welding with gaps

> Ensures better penetration from both sides of the pipe

> Ideal for vertical up and vertical down welds.

INCONEL fa riferimento alla famiglia delle superleghe a struttura austenitica a base di nichel-cromo. Altri nomi commerciali usati per indicare questa lega sono Chronin, Altemp, Nickelvac e Nicrofer. L’Inconel una lega, principalmente a base di nichel (48%-72%) e cromo (14%-29%).

Presenta un’ottima resistenza all’ossidazione alle alte temperature ed alla corrosione; per queste sue caratteristiche viene impiegato in parti di turbine a gas, nel settore petrolifero (per esempio per il rivestimento interno dei tubi), negli inceneritori di rifiuti RSU/industriali tossico-nocivi, per la protezione dei tubi di caldaia a recupero, fissato con saldatura o con termal spray, per la realizzazione delle scatole nere degli aerei e nell’industria chimica.

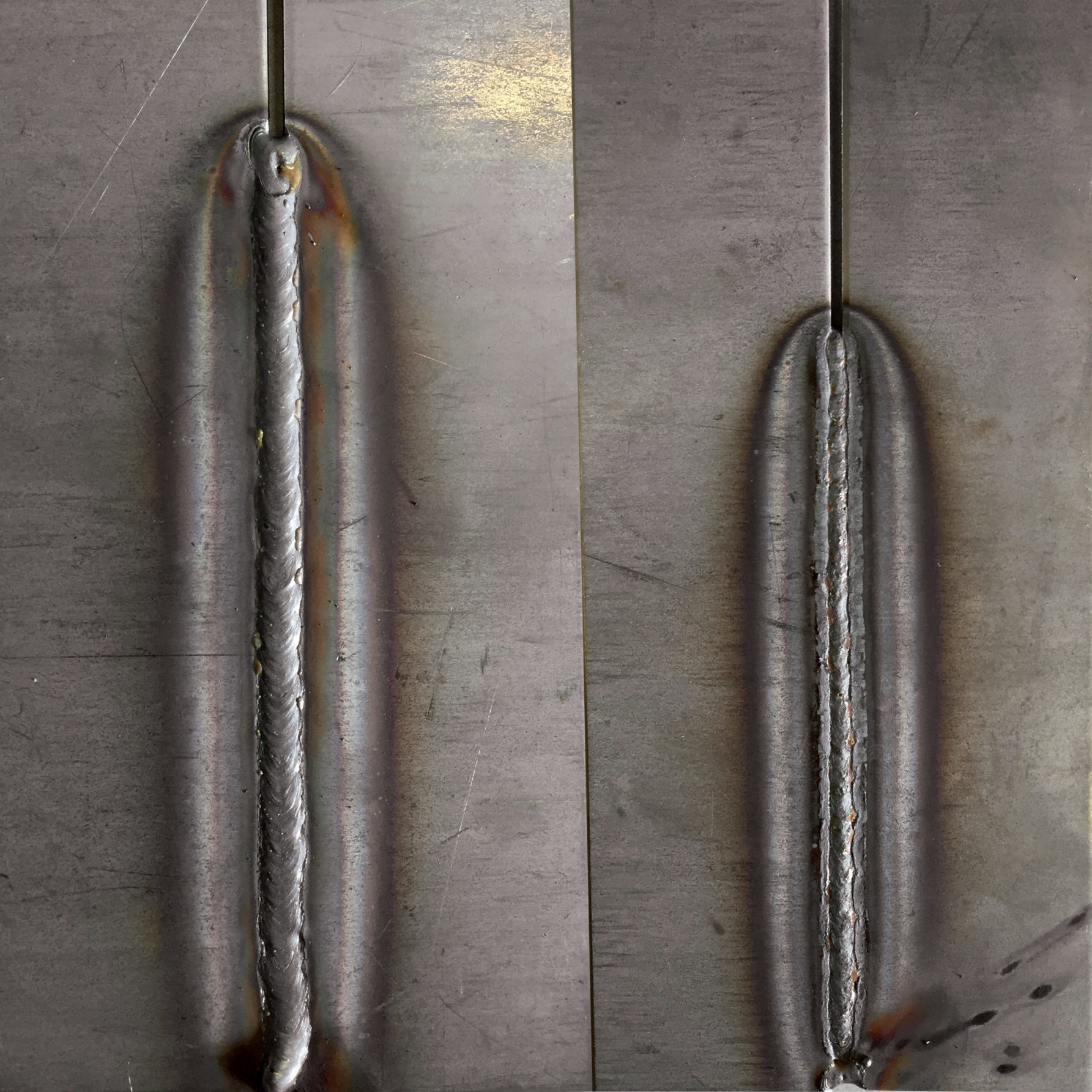

MAX 453 TOP 504 XXM

Giunta testa testa.

Materiale SMO 254 spessore 4mm. Materiale d’apporto Inconel.

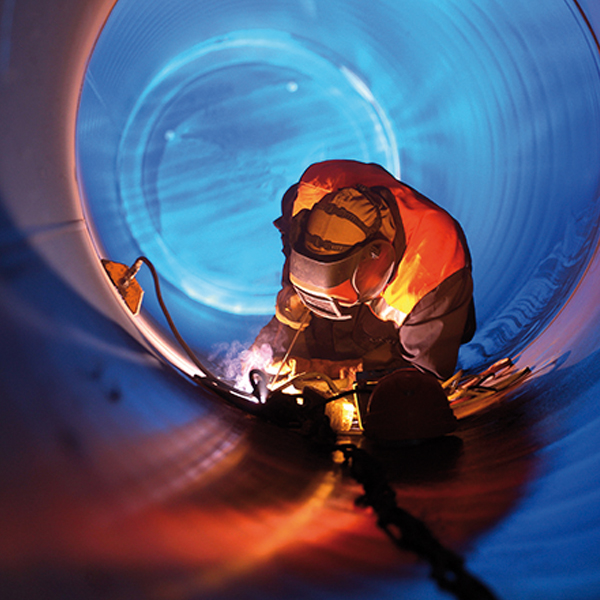

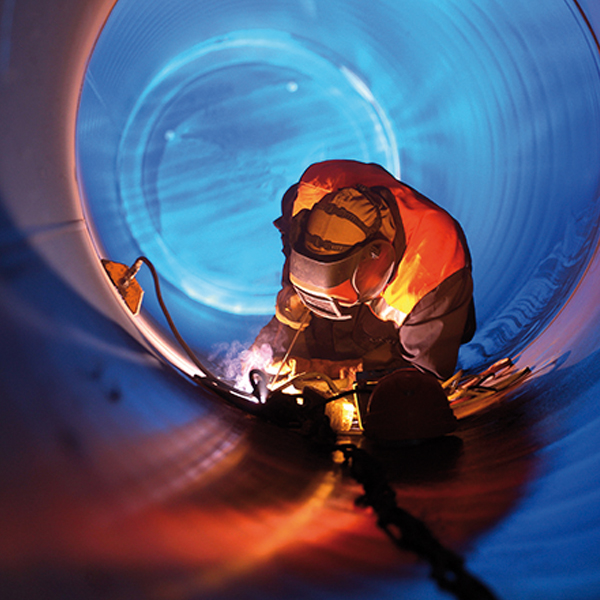

MAX 603 TOP 504 XXM

Collettore alta pressione.

Materiale P11 Sp 10 mm il collettore e 35 mm il fondello.

ST-ARC™ is the intelligent control of the Short Arc process, capable of handling automatically all variations within the welding process.

The result is a short concentrated and stable arc 100% easier to control. The dynamic cold welding characteristics significantly lower the heat input reducing distortion, spatters, re-working and cleaning plus less weld time.ST-ARC™ is a standard feature of all Stel MIG / MAG Stel welders.

SELF COMPENSATION

Automatically compensates for any variation in

welding conditions caused either by irregularities of

the workpiece or the movements of the operator’s

hand. Ideal for awkward angles.

START CONTROL

The approach speed of the wire to the piece and welding dynamics are synergic and provide limit spatters at the start with every material.

The dynamic synergic technology provides for an extremely smooth, spatter free Arc Ignition with all materials.

VERTICAL POSITION

In a vertical UP position allows welding of thin material with separation up to 5mm gap.

THIN MATERIALS

Provides a smooth, controlled arc too at the lowest parameters with few spatters, good weldability of the edges, heating and reduced deformations for thin materials.

PAW™ is Precision Aluminium Welding. A new intelligent arc welding control on very thin Aluminium.

The result is a very short and concentrated welding arc using 1.0mm wire with a standard MIG Torch.Therefore, there is no need for expensive push-pull torches, plus the additional cost saving of

using smaller wire diameters that cause problematic feeding.

PROGRAMS

There are 12 programs dedicated to aluminum.

Programs are synergic and pulsed. Two PAW™ programs (AlMg5 and AlSi5) are available for thin material thicknesses from 1 to 2mm.

PULSE

Preset synergic pulse programs greatly assists the operator with welding materials such as aluminum.

ALUMINUM

Owing to PAW™ technology, the IRON-MIG 221P power source can weld AlMg5 and AlSi5 aluminum wires avoiding the use of expensive push-pull torches and smaller diameter wires.

Normally pulsing is a “HOT” process. This has always caused problems of metal distortion (in particular thin material) and working speed.

Achieving a fast process has been the manufacturer’s challenge of the last years.

New processes have developed with many different names under the title SPEED.

What about the HEAT?

This is the real challenge that STEL has taken with the innovative i-Cold Pulse™. Reducing the thermal heat STEL have been able to increase the welding speed by 35%.

The arc is more concentrated and intense granting a better penetration.

i-Cold Pulse™: reduce heat input by improving performance

Find out how the Stel pulsed system reduces heat input by increasing speed by 35%. Many have tried, Stel has succeeded.

Normally you know the pulsed welding in TIG and MIG, But not the pulse in electrode.STEL has been the first to develope this procedure with the range Max dp 171.-201C presented at ESSEN in the 2005.

Today this process has been studied and appreciated in all the European Universities of Welding.

The benefits

SELF COMPENSATION

> Better arc stability (expecially at low currents)

> Possibility to use the electrode with bigger diameter with thin materila thickness.

> Reduction of breakthroughs during welding with thin material thickness

> Better transfer control of the welding arc

> Easier control for the welder

> Improvement of the aesthetics of welding very similar to the Tig expecially with 4-5Hz frequency.

START CONTROL

> Ensures better and safer welding with gaps

> Ensures better penetration from both sides of the pipe

> Ideal for vertical up and vertical down welds.

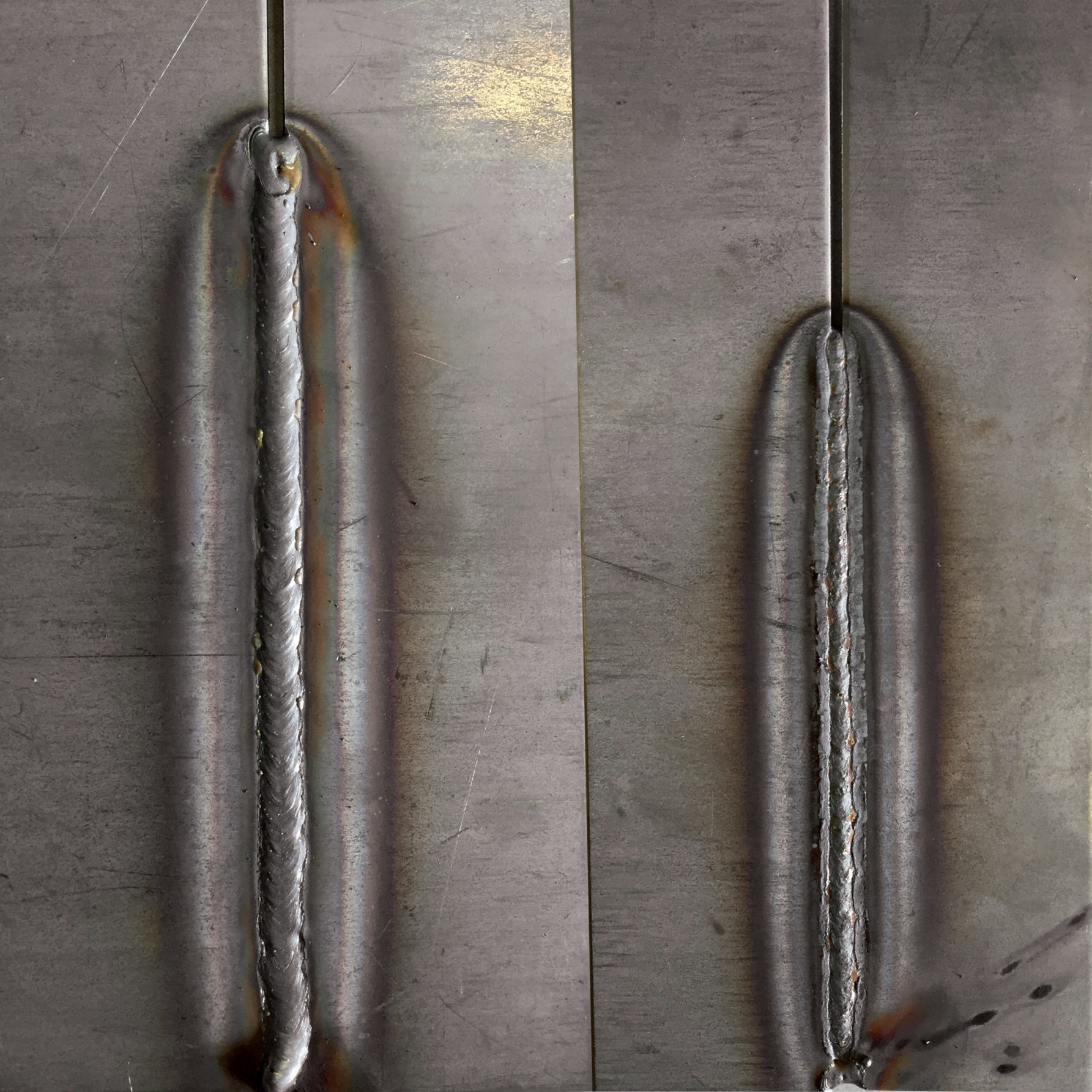

MAX 453 TOP 504 XXM

Giunta testa testa lamiere da Sp 4mm.

Materiale SMO 254. Materiale d’apporto Inconel.

MAX 603 TOP 504 XXM

Collettore alta pressione.

Materiale P11 Sp 10 mm il collettore e 35 mm il fondello.

INCONEL fa riferimento alla famiglia delle superleghe a struttura austenitica a base di nichel-cromo. Altri nomi commerciali usati per indicare questa lega sono Chronin, Altemp, Nickelvac e Nicrofer. L’Inconel una lega, principalmente a base di nichel (48%-72%) e cromo (14%-29%).

Presenta un’ottima resistenza all’ossidazione alle alte temperature ed alla corrosione; per queste sue caratteristiche viene impiegato in parti di turbine a gas, nel settore petrolifero (per esempio per il rivestimento interno dei tubi), negli inceneritori di rifiuti RSU/industriali tossico-nocivi, per la protezione dei tubi di caldaia a recupero, fissato con saldatura o con termal spray, per la realizzazione delle scatole nere degli aerei e nell’industria chimica.